Intelligent Digitization of Operational Workflows

Perform without waste from order to delivery

Why  ?

?

Customers

Shorter and more robust repeatable flow times

Fast returns to customers

Interactive responses to customer requests

Supply-chain and logistic

Control of operational volume at the agreed upon aligned capacity.

Streamlined and visual processes

Adaptation to market volumes and mix

Production units

Simplification of operational management

Increased productivity

Maximization of the volume produced

Digitization of production areas

Clear and visual operational processes, just what is needed and easy to understand

Conditions met so that everyone in the company can fulfill their missions and apply their standards

How

How An intelligent system parameterized according to the specificities of your processes.

Valessentia

- At the head of the expertise in Operational Excellence for 30 years.

- Cutting-edge and uncommon know-how in flow management.

Intelligent

- Automated to the right need

- Equipped with personalized algorithms

Poussé-tiré

- Production oriented

- Designed to ensure performance

What is it  ?

?

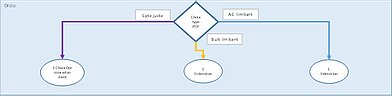

A visual and interactive pull system

Visuel

- Visual 83% of people perceive information by sight

Interactif

- Easy to understand

- User-friendly

- Universal dissolver of variability

Pull

- Pull Absorbs customer needs

- in volume variation

- in mix variation

- in fluctuation speed

- Optimizes the use of resources

- Keeps information flows and physical flows perfectly aligned.

A field-oriented tool adapted to the process to be managed:

a customer-oriented tool that is agile in the market

a process-oriented tool ensuring the shortest flow times

a capacity-oriented tool ensuring the lowest costs.

a Total Quality oriented tool ensuring the best performances.

a logistics-oriented tool ensuring

the right item

in the right place

at the right time.

a user-oriented tool ensuring a clear understanding for each person involved

It can include

a logistics box supporting the order book

a synchronization box for production and logistics processes

a production rate control table (Takt time)

a leveling box (Heijunka)

control rails (sequencers)

It pilots the physical flows

with interactive kanbans

in direct connection with the physical flows